VERtical Separators

OTSO offers a wide variety of Vertical Separators specifically designed to perform unique functions. Our Engineering team is in constant pursuit of more efficient and economical ways to increase production. Vertical Separators are typically used for managing medium gas/oil ratios, although OTSO’s Vertical Separator lineup covers a much wider range of applications.

OTSO engineers utilizes best in class internal technologies such as Computational Fluid Dynamics (CFD) software to achieve each clients required performance. Our engineers also use these same technologies to design patented and proprietary equipment in their constant pursuit of identifying enhanced methods of separation.

Our standard Vertical Separator lineup offers configurations that efficiently separate oil, gas & water. We also offer specialty Vertical Separators that excel at handling non-typical gas/oil ratios and other often seen problems such as foam, paraffin and hydrates while lowering maintenance, downtime and costly separator carry over.

OTSO offers unique proprietary designed internals that reduce costly separator carry over, while lowering maintenance and downtime. In addition, our engineering team can outfit your Vertical Separator with OTSO’s PureSEP™ internals to meet your specific separation requirements.

Benefits

- Variety – OTSO’s Vertical Separator Lineup Covers All Applications

- Utilize OTSO’s PureSEP™ Internals for Optimum Performance

- Easy Sand & Paraffin Removal During Service

- Easily Equipped with Solids Removal System

TYPES

Vertical Up-FLO™ Separators

A COST EFFECTIVE & DEPENDABLE SOLUTION FOR GAS/LIQUID SEPARATION

OTSO’s Vertical Up-FLO™ Separator is designed to extract small amounts of solids and liquids form the inlet vapor stream. With removal rates of 98 – 99% and 5 – 10 Micron depending on demisting media, they are also the most common Vertical Separator in the industry for gas scrubbing applications. This reliable and cost effective unit is considered the go to option for low pressure / low flow rate operating conditions.

Although design configurations can vary, standard Vertical Up-FLO™ Separators are commonly configured with a side mounted inlet, top mounted gas outlet, side mounted oil outlet and a side mounted water outlet. Allow our engineering team to outfit your Vertical Up-FLO™ Separator with OTSO PureSEP™ internals for safe, continuous operation and dramatic increases in scrubbing performance.

How IT Works

Vertical Up-FLO™ Separators regulate inlet momentum, vapor demisting, liquid retention and liquid outlets to meet your specific separation requirements.

Inlet Momentum can be regulated with a standard inlet diverter or with OTSO’s Maelstrom Revolution™ for maximum bulk gas / liquid separation.

Vapor Demisting is the coalescing and ultimate removal of liquid droplets from the gas stream. Wire mesh is the traditional choice for demisting but should be avoided when high paraffin / heavy crude operating conditions are present. In these situations, OTSO’s PureSEP™ serpentine vanes or coalescing ball media are the recommended choice for demisting internals.

Liquid Retention occurs after inlet momentum disbursement, when liquids fall to the liquid retention area at the bottom of the vessel for further separation. The liquid retention area in vertical separators is inherently limited, as such, calculating liquid retention time for adequate coalescing to occur is extremely important. Factors such as crude oil gravity, BS&W and operating temperature are the key components used when calculating liquid retention area. Due to the limited liquid retention space available in Vertical Separators, PureSEP™ internals are routinely incorporated to reduce liquid / liquid coalescing time.

Liquid Outlets located at the bottom of the vessel use internal components such as weirs, baffles and vortex breakers to prevents re-entrainment. OTSO’s engineering team is highly apt in configuring the liquid outlet section of vessels and can offer assistance to ensure proper configuration.

Applications

Vertical Up-FLO™ Separator has been used successfully in the following applications.

- Vertical Fuel Gas Scrubbers

- Vertical Gas Vent Vessels

- Vertical Surge Vessels

- Vertical Test Separators

- Small Vertical Slug Catchers

- Small Vertical Production Separators

Downloadable Resources

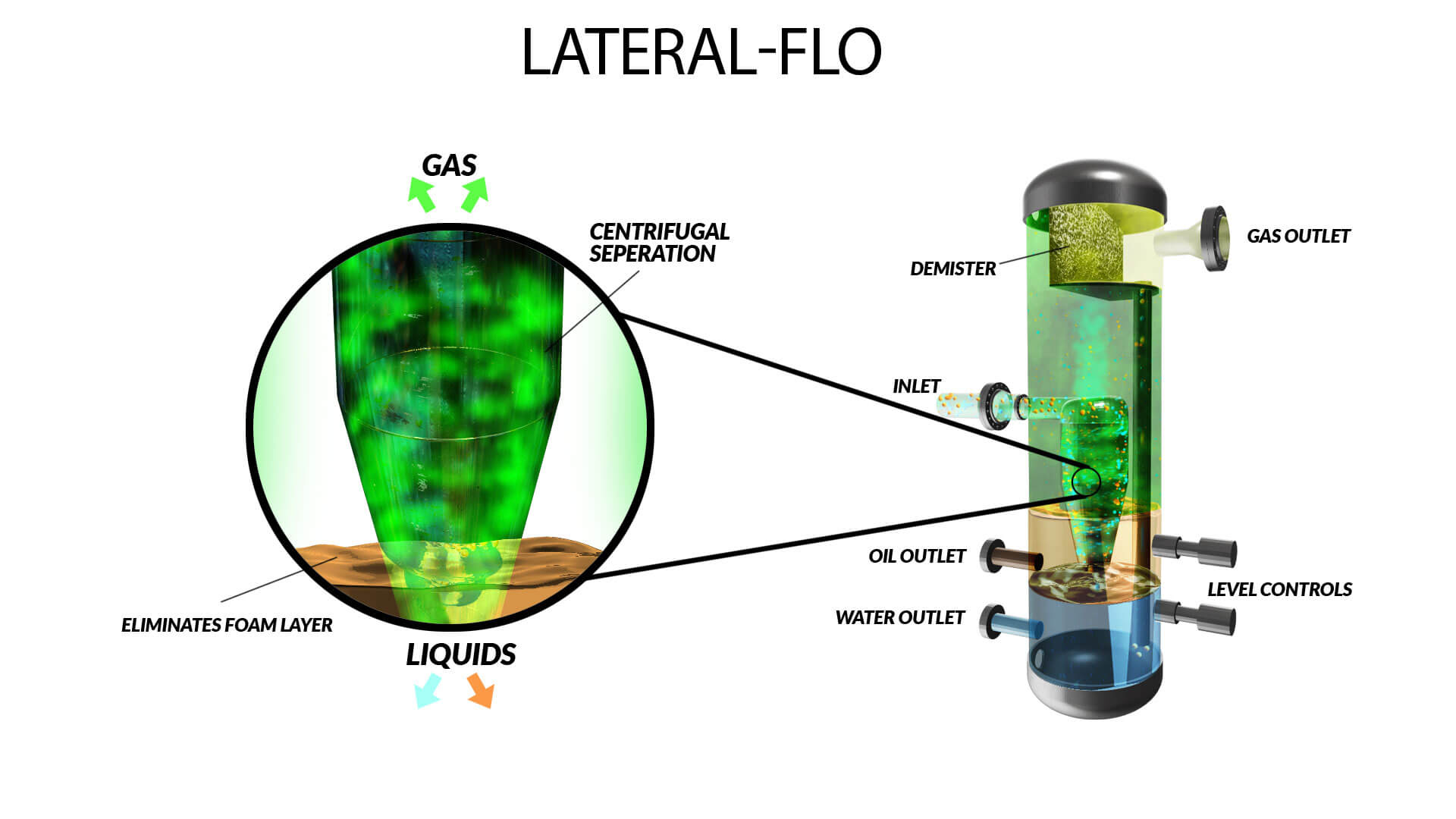

Vertical Lateral-FLO™ Separators

A RELIABLE, VERSATILE, AND DEPENDABLE SOLUTION FOR GAS/LIQUID SEPARATION

How IT Works

Vertical Lateral-Flow™ Separators function in a similar manner to Vertical Up-FLO™ Separators in regards to the regulation of inlet momentum, vapor demisting, liquid retention and liquid outlets.

Inlet Momentum can be regulated with a standard inlet diverter or with OTSO’s Maelstrom Revolution™ for maximum bulk gas / liquid separation.

Vapor Demisting is the removal of liquid droplets from the gas stream through coalescing. As the gas flows laterally across the demisting media, entrained liquids are removed from the gas. The removed liquids are then collected and drained via the downcomer pipe to the liquid retention area. Wire mesh is often selected for demisting, although it should not be used in high paraffin / heavy crude applications. In high paraffin / heavy crude operating conditions, OTSO’s PureSEP™ coalescing ball media or serpentine vanes are recommended for demisting internals configuration.

Liquid Retention occurs after the inlet diverter has performed bulk gas / liquid separation. At this point, liquids fall to the liquid retention area at the bottom of the vessel for further separation via coalescing. This area of the vessel is typically separated using a degassing baffle. The liquid retention area of vertical separators is inherently limited, therefore, calculating enough liquid retention time to allow sufficient coalescing to occur is extremely important. Operating conditions such as Crude Oil Gravity, BS&W and Operating Temperature are used when calculating liquid retention time. With the limited liquid retention space available in Vertical Separators, OTSO’s PureSEP™ internals are routinely used to reduce liquid / liquid coalescing time.

Liquid Outlets located at the bottom of the vessel use internal components such as weirs, baffles and vortex breakers to prevent re-entrainment. OTSO’s engineering team is highly apt in configuring the liquid outlet section of vessels and can offer assistance to ensure proper configuration.

Applications

Although highly versatile in performance, the Vertical Lateral-FLO™ Separators internals are a bit more involved. Because of this, we typically reserve the Vertical LateralFLO™ Separator for larger, high pressure applications.

The Vertical Lateral-FLO™ Separator performs exceedingly well in small and low pressure operating conditions. However, the internal complexity of the vessel makes it less price competitive than other options available for small and low pressure applications.

- Vertical Inlet Separators

- Vertical Wellhead Separators

- Vertical Test Separators

- Vertical Production Separators

- Vertical Slug Catchers

- Vertical Flash Separators

Downloadable Resources

Vertical CENTERFLO™ Separators

INCREASE CAPACITY WITH HIGH THROUGHPUT PERFORMANCE

How IT Works

After bulk gas / liquid separation at the inlet baffle, gas flow centralizes and enters the circular fixed vane. Gas flow further decelerates while flowing through the vane for enhanced coalescing of liquids, while even disbursement across the circular vane increases throughput. Removed liquids are collected and drained with a downcomer pipe to the liquid retention area for further separation.

Inlet Momentum is either regulated with a standard inlet diverter or with OTSO’s Maelstrom Revolution™ for maximum bulk gas / liquid separation.

Liquid Retention occurs after the inlet diverter has performed bulk gas / liquid separation and as liquids enter via the downcomer pipe. At this point, liquids fall to the liquid retention area for further separation via coalescing. The liquid retention area of vertical separators is inherently limited, therefore, calculating enough liquid retention time to allow sufficient coalescing to occur is extremely important. Operating conditions such as Crude Oil Gravity, BS&W and Operating Temperature are used when calculating liquid retention time. With the limited liquid retention space available in Vertical Separators, OTSO’s PureSEP™ internals are routinely used to reduce liquid / liquid coalescing time.

Liquid Outlets located at the bottom of the vessel use internal components such as weirs, baffles and vortex breakers to prevent re-entrainment. OTSO’s engineering team is highly apt in configuring the liquid outlet section of vessels and can offer assistance to ensure proper configuration.

Applications

- Easier to retrofit and increase existing equipment capacity due to Radial design.

- Radial design reduces vessel diameter and overall footprint

- Ideal for high gas flow rate applications with low liquid volumes without the possibility of slugging

- Radial serpentine vane is contaminant resistant making the unit suitable for sticky / viscous fluids.

Downloadable Resources

Vertical CycloSPIN™ Separators

HIGH PERFORMANCE LIQUID/SOLIDS REMOVAL FOR WELLHEAD & PIPELINE APPLICATION

The cyclonic power of the Vertical CycloSPIN™ Separator is second to none. This exceptionally strong and efficient unit yields liquid and solid separation results of 99.9% up to 7 microns, without erosion of vessel walls and internals. Reductions in catch efficiency are non-existent from hydrates, solids and even small liquid slugs, they are simply no match for this powerful vertical separator.

The Vertical CycloSPIN™ Separator is remarkably forgiving, as it covers a wider range of liquid / solids ratios, pressures, and flow rates than any unit in our portfolio.

How IT Works

The Vertical CycloSPIN™ Separator is the result of enhancements to traditional cyclonically designed separators. When proper regulation and restriction of flow and turbulence are achieved, liquid / solid re-entrainment is essentially removed.

Centrifugal force is used to cast liquid and solid particles against the vessel walls separating them from the gas. The gas then enters the centrally located inverted vortex, rises and exits the vessel through the top mounted gas outlet.

The discarded solids and liquids adhere to the vessel walls, flow down and exit the bottom vessel’s outlet.

As gas and liquids enter the vessel, flow is regulated by a centrally mounted inlet vs. a side / tangentially mounted inlet that’s typically seen in Cyclonic Separators. The CycloSPIN™ centrally mounted inlet creates a low velocity area upon vessel entry. This low velocity area provides advanced separation efficiency by keeping liquid and solids droplets large. If cyclonic spinning occurred immediately upon gas and liquids entering the vessel, the large liquid / solids droplets would reduce in size, thereby reducing separation efficiency.

Next, wet gas enters the fixed blade cyclonic device, where constrictions in flow space force gas rotation to rapidly accelerate. The centrifugal force created in this process casts liquids / solids of the gas to the vessel walls to remove virtually all liquid / solid contaminants.

CycloSPIN™ Separator Design Provides:

- 99.9+% Liquid/Solids Separation

- No Contaminate Collection

- No Erosion

- High Turndown Ratio

- Highly Proficient Solids Removal

- Small Footprint via Vertical Design

- Adsorbs Liquid Slug Momentum

CycloSPIN™ Separator Design Advantages:

- Controlled Flow

- Prohibits Secondary Turbulence

- Effectively Eliminates Re-Entrainment of Liquid & Solid Particles

- Centrifugal Force Conversion to Inverted Vortex

- Radial Inlet in lieu Tangential

- Stage 1 Reduced Velocity Separation for Large Droplet Collection

- Stage 2 Constricts Flow Space to Increase Velocity for Further Separation

- Designs Available to Cover

- Wide Flow Rate Capacity: 5MM – 500MMsctd

- 3 – 10 psig Pressure Drops

Vertical SpiralFLO-V™ Separators

High Performance Centrifugal Force Gas/Liquid Separator

The Vertical SpiralFLO-V™ centrifugal force separator is compact, light-weight and efficient. Performance expectations are greater than or equal to vane units with liquid separation yields of 99.9% up to 10 microns. This unit is designed for operating conditions with up to 500 BBL of liquids per mmscf.

How IT Works

Initial bulk liquid separation starts with the SpiralFLO-V™ tangential inlet. The tangential inlet generates centrifugal force, thereby casting liquids against the walls of the vessel to separate them from the gas. Liquids are cast against the vessel walls then flow down the vessel and enter the liquid retention area.

Second stage separation happens as centrifugal force spins gas along the vessel walls in a downward motion. This downward spiral results in gas migrating to the center of the vessel for entry into the vortex tube. Once inside the vortex tube, centrifugal force rapidly increases gas velocity to further eliminate entrained liquids from the gas.

As gas rises toward the outlet, entrained liquids rise up the vortex tube. At this point, Liquids and a small percentage of gas exit a small opening at the top of the vortex tube to create a side gas / liquids stream. The differential pressure at the bottom of the vessel creates the low pressure area required for the vortex tube and side gas / liquids stream to operate.

Applications

OTSO’s SpiralFLO-V™ has performed successfully as:

- Vertical Gas Production Separator

- Vertical Gas Test Separator

- Vertical Geothermal Separator

- Vertical Steam Separator

- Vertical Fuel Gas Scrubber

- Vertical Flare Scrubber

- Vertical Inlet Gas Separator

- Vertical Gas Injection Separator

- Vertical Contactor

- Vertical After-Scrubber

Vertical Down-FLO™ Cyclone Separators

Affordable and Compact Bulk Gas/Liquide Separation

How IT Works

Primary bulk gas / liquid separation occurs as process fluids enter the Vertical Down-FLO™ Separators tangentially mounted inlet nozzle. The tangential inlet is mounted at a downwardly sloped angle, creating enough centrifugal force to form a liquid vortex in the center of the vessel, which allows rapid bulk gas / liquid separation to occur. As gas exits the top outlet, the vortex discards entrained liquids against the vessel walls where they flow down to the liquid retention area for removal.

Regulating Vertical Down-FLO™ Separator is done with either active or passive separation. When using Passive Separation, liquid and gas combine downstream at an elevation equal to the liquid level setting of the Vertical Down-FLO™ Separator. Active Separation is achieved with a liquid control valve at the liquid outlet and regulated by a differential pressure transmitter, or a back pressure valve at the gas outlet. Another means of regulating the vessel through Active Separation is to install a slug suppression and liquid control valve at the inlet.

The principal designed performance objective of the Vertical Down-FLO™ Separator is to provide efficient, cost effective bulk gas / liquid separation in a small footprint vessel. Although the vessel can be designed to meet the specific performance criteria required for each applications operating conditions, traditional designs yield gas outlet ranges of 0.5 – 2.0 gallons of liquids per MMscf and liquid outlet yields of up to 5% Gas Volume Fraction (GVF).

Applications

The Vertical Down-FLO™ is ideally suited for liquid/gas ratios in excess of 50 BBL of liquid per MMscf of gas.

OTSO’s GLCC has performed successfully in the following applications:

- Vertical Test Separators

- Vertical Inlet Separators

- Vertical 2 Phase Production Separators

- Debottlenecking Applications

Maelstrom Revolution

Maelstrom Revolution

Superior Gas/Liquid Separation & Foam Elimination

OTSO’s Maelstrom Revolution™ provides superior inlet momentum regulation through the dissipation of fluid energy. Traditional inlet control devices such as a splash plate or dished head simply can’t compete with the performance of this innovative unit. The Maelstrom Revolution™ utilizes centrifugal force to rapidly accelerate oil, water and gas from the inlet stream. An additional benefit of this unit is its ability to eliminate foam.

Such efficiency at the initial separation phase has a profound impact on overall separator function. In fact, reduction in vessel size is the norm when the Maelstrom Revolution™ is incorporated.

The importance of better separation and foam elimination is not merely a performance benefit. It also carries with it a positive impact on our clients bottom line. Simply put, better separation yields higher oil and gas recovery.

HOW IT WORKS

The Maelstrom Revolution™ is a tangential inlet separation device flanged connected to the inlet nozzle. Its tangentially mounted inlet and single spiral-tubular arrangement creates extreme centrifugal force that generates a spinning motion at the inlet phase. As centrifugal spinning ensues, liquids and solids are forced to the walls of the Maelstrom Revolution™. Throughout this spinning process, gas rises and exits, while liquids casted to the Maelstrom Revolution™ walls further separate and fall into the vessels liquid retention area.

Reduces Vessel Size & Weight

To mitigate foam disengagement concerns, it’s common practice for engineering design vessels with excess capacity. The Maelstrom Revolution™ is the solution to such issues due to its ability to not only eliminate foam and rapidly separate gas and liquids at higher flow rates than traditional inlet devices. As a result, considerable reductions in vessel footprint and weight are experienced in separators containing a Maelstrom Revolution™.

APPLICATIONS

The Maelstrom Revolution™ is suited for any application involving the separation of gas, liquids and solids. The Maelstrom Revolution™ is especially apt at mitigating foam, making it the ideal choice for applications requiring foam elimination.

The Maelstrom Revolution™ has been used successfully in the following applications.

- Production Separators

- Test Separators

- Scrubbers

- Slug Catchers

- Free Water Knockouts (FWKO)

BENEFITS

- Excess Capacity for Foam Management is not required, Eliminates Foam and Improves Flow

- Retrofitting Available – If Manway is Present, Dramatic Debottlenecking Results are Achieved

- Suitable for Vertical and Horizontal Applications

- Removal of Carryover Liquids in Outlet Gas Stream

- Reduces Sediment and Emulsion

- Reduces / Eliminates De-foaming Chemical Cost

- Minimized footprint, reduced weight and ease of installation

PureSEP Horizontal Filter Internals

PureSep™ HORIZONTAL SEPARATOR INTERNALS

High Performance Oil/Water Separation

We’re redefining what’s possible with oil/water separation with the release of our PureSep™ Coalescing Ball Media (PS-CB). The PureSep™ Coalescing Ball medias unique design maximizes surface area allowing gravity to separate oil and water with extreme efficiency. Superior performance is achieved in both heated and ambient separation systems such as Free Water Knockouts (FWKO), and capable of handling high mix oil/water dispersions and covers all API oil gravities.

Smaller Vessels w/ Increased Volume

PureSep™ PS-CB’s improves separation efficiency by causing oil droplets to rapidly coalesce into larger size droplets which rise much faster than the smaller droplets seen in standard coalescing media.

As such, separators outfitted with PureSep™ Coalescing Ball media experience increases flow rates allowing for smaller, more efficient vessels that save you money.

Why PureSep™

- Cleanout – Random packing can easily be removed and cleaned. Without fixed or moving parts PS-CB media simplifies routine maintenance and cleaning.

- Water Quality – Can remove 98.5% of oil particles with proper chemical treatment.

- Reduces BS&W Content – High quality discharge equals separation efficiency and reduced fuel requirements.

- Chemical Costs Savings –High performance can reduce chemical dosages costs as much as 50%.

- Consistent Performance – Even under variable conditions, PureSep™ Coalescing Ball media tolerates mixed operating conditions such as flow rates, solids contamination and oil/water blends.

- Reduces Space – The PS-CB system is efficient, allowing a smaller vessel to withstand higher flow-rate capacities with increased separation proficiency.

- Plugging Resistant – PS-CB systems unique ball spacing design minimizes common plugging problems experienced by other coalescing methods.

- Perfect for Retrofitting – PureSep™ Coalescing Ball media easy to install, making it the perfect coalescing replacement option for separation vessels.

PureSep™ Corrugated Plate (PS-CP)

OTSO’s PureSep™ PS-CP Coalescing Media is a long standing, high performance separation system. Its fitted, open matrix and compact design contains a high surface area that increases coalescing while minimizing plugging.

Features Include:

- High surface area per Ft3

- Plugging Resistant Design

- Material Based on Temp. – Stainless Steel, Carbon Steel, PVC & Polypropylene

- Space efficient design

PureSep™ Vane (PS-V)

In most cases, serpentine vane mist extractors are efficient in gas/liquid separation and are effective in both vertical separators and horizontal separators.

Vane spacing and shape allow coalescing to occur and separate into small liquid particles without plugging. The serpentine vane pack is located vertically in the separator allowing for velocity to increase by approximately 40% as the gasses pass between the serpentine vane plates, causing liquid particles to collide against the plate walls to scrub liquids from the gas stream.

PureSep™ Wire Mesh (PS-WM)

Wire mesh is another method of removing particles from the gas stream and is typically used at the gas outlet for final clean-up. Wire mesh has tightly grouped wires that rely on droplet coalescing from gas flow as its separation mechanism.

Due to plugging concerns from common gas impurities such as paraffins, asphaltenes and salts, wire mesh is only recommended for applications where a clean inlet gas stream is present.